High-precision coverage unique to wet plating

Compatibility of mechanical properties of dry coating

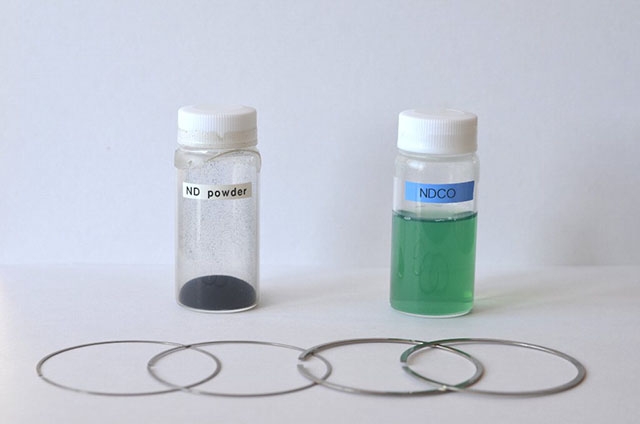

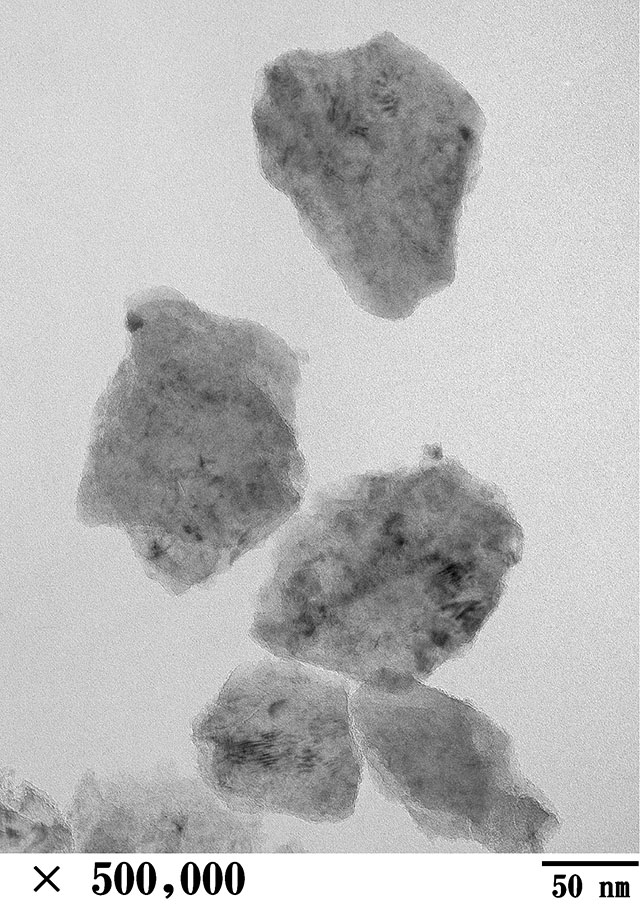

For the first time in the world, it has been possible to uniformly disperse and co-deposit nano-diamond (ND) particles on the order of 10 to 100 nm, which has been difficult to obtain evenly co-deposited composite plating.

(Patent No. 5435477)

- Compositing single particles into Ni-P plating film using our proprietary nanodiamond dispersion technology.

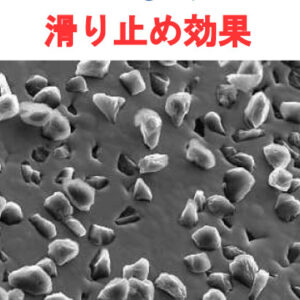

- Achieves high strength, low friction, and low aggression due to nano-order.

NDCO plating solution (right)

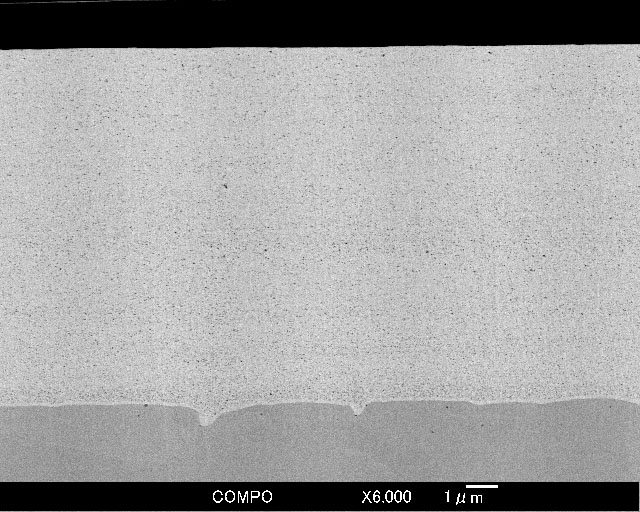

(SEM: 6000x)

(TEM 500,000x)

Features

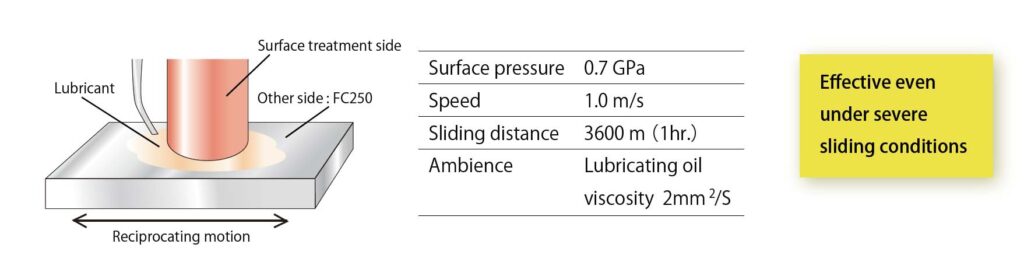

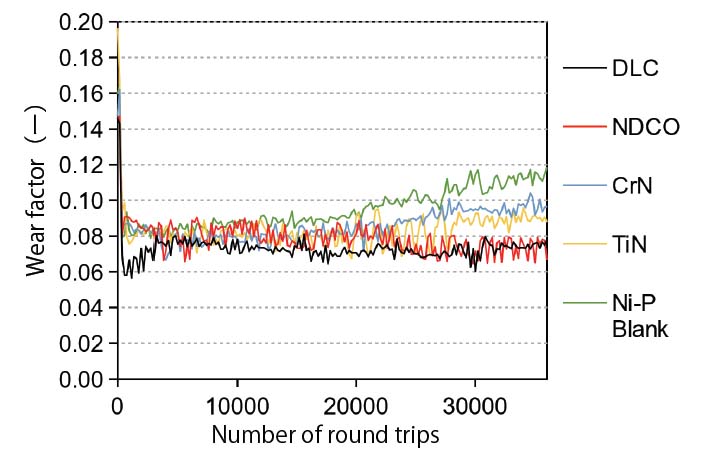

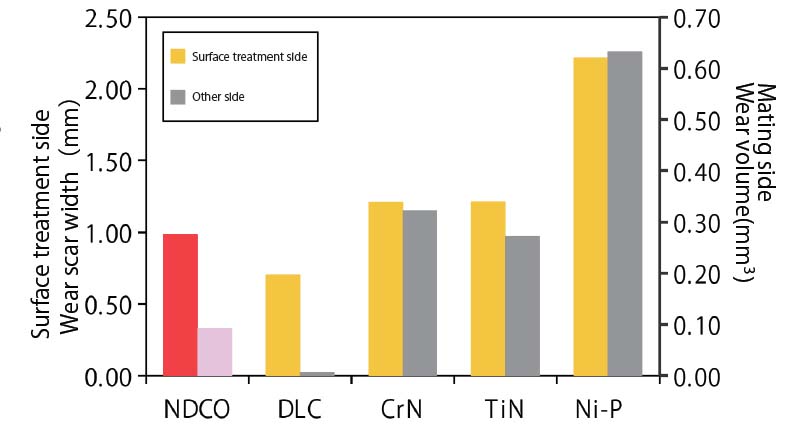

- Friction coefficient equivalent to DLC in a sliding test environment with poor lubrication

- 20% less self-wear and 70% less mating material wear compared to TiN and CrN

- It is difficult to dry-coating (TiN, CrN, etc.), and it is possible to coat evenly with high film thickness accuracy on complicated parts with severe dimensional accuracy, the inside of tubular parts, etc. ⇒ Excellent throwing power.

- Construction is possible regardless of the material, such as die-casting or plastic.

| Throwing performance | Hardness | Wear resistance | Low aggression | Processing cost | |

| NDCO | ◎ | At normal temperature : HV. 550 with heat treatment : HV. 1000 | 〇 | ○ | ○ |

| DLC | △ | HV. 2000~3000 | ◎ | ◎ | △ |

| CrN | △ | HV. 2000~2200 | 〇 | △ | △ |

| TiN | △ | HV. 2000~2500 | ○ | △ | △ |

| NiP | ◎ | At normal temperature : HV. 550 with heat treatment : HV. 1000 | X | X | ○ |

NDCO technical data

Correspondence size, specifications

| Correspondence size | Maximum: 200mmx200mmx200mm |

|---|---|

| Hue | Silver |

| Workable base material | Please contact us. |

| Deposition accuracy | ±1μm |

| Hardness | (No heat treatment):Hv500~600 (with heat treatment):Hv900~1000 |

| AdhesionScratch test (load ~ 100N): no peeling | Scratch test (load ~ 100N): no peeling |

| Heat-resistant | TG/DTA measurement: exothermic peak at 560 degrees |

| Thermal conductivity | 0.100~0.140(cal/cmS℃) |

| Electrical resistance | 6.2×10-6Ωcm |

| Coefficient of thermal expansion | 12×10-6/℃ |

Contact for "NDCO"

<New Business Development Division>

Tel : +81-778-51-5000 → 9 → Extension number 317

Fax : +81-778-51-4710

Person in charge : Mr. Osada

E-meil : Takuya_Hisaka@eyetec.co.jp