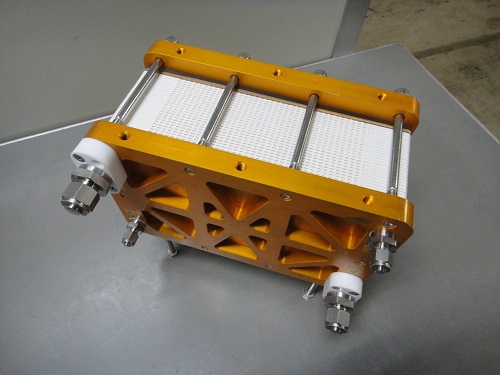

The technology and development business consists of the following two divisions.

1. A development department that develops new technologies for developing new businesses based on surface treatment

2. Technical department that develops and proposes new products and new technologies for existing business divisions

We mainly focus on new technology development and research and development of subsidized projects.

Aiming at EYETEC's vision of "What the world doesn't have! EYETEC of technology", we have built a technology development system rich in ideas by consolidating basic research and applied technology into one department. We conduct market analysis, etc. based on new inquiries from customers and requests from the Surface Treatment Division, etc., and select and work on themes. We are conducting various researches such as research that utilizes existing technology and development of technology that does not exist in the world.