What is ion plating (Physical vapor deposition)?

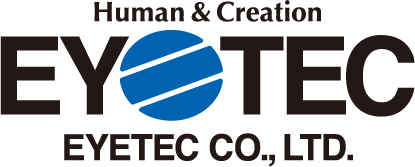

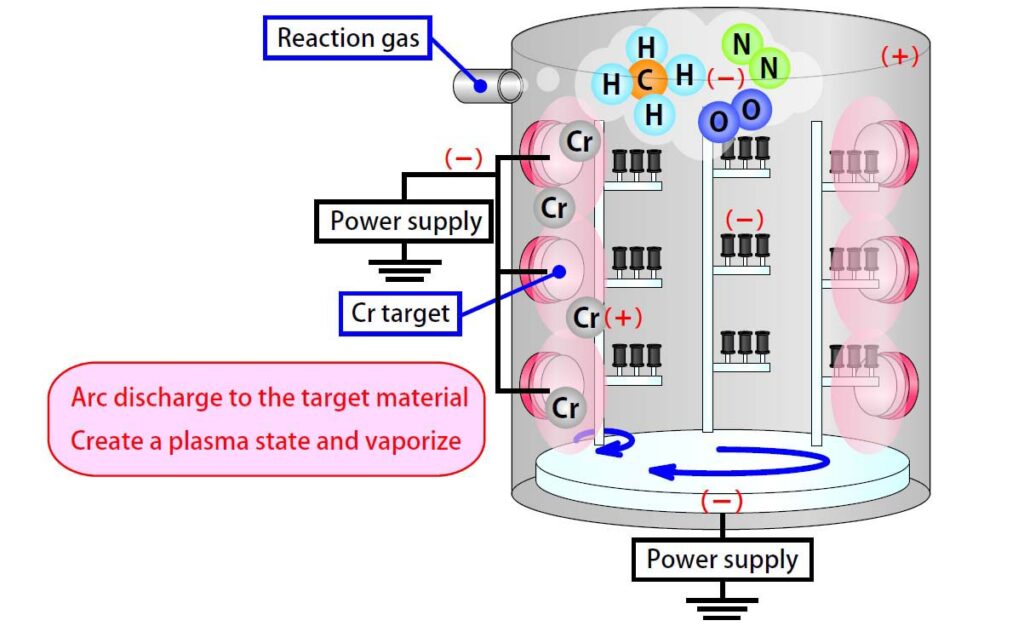

Ion plating (physical vapor deposition: PVD) is a deposition method in which metals such as titanium and chromium, which have been converted into plasma in a vacuum, react with nitrogen, carbon, and oxygen to form a ceramic coating.

Our company owns approximately 20 PVD facilities using three methods: electron gun fusion ion plating, arc discharge ion plating, and magnetron sputtering. This allows us to select the processing machine that best suits your workpiece size and required film deposition conditions. We specialize in decorative coloring using ion plating, which gives metal products resistance to scratches, abrasion, and peeling, as well as excellent corrosion and weather resistance. Furthermore, we can process workpieces in shapes ranging from spherical to long, and we have experience using ion plating on electrically non-conductive insulating materials.

Features of our ion plating coloring

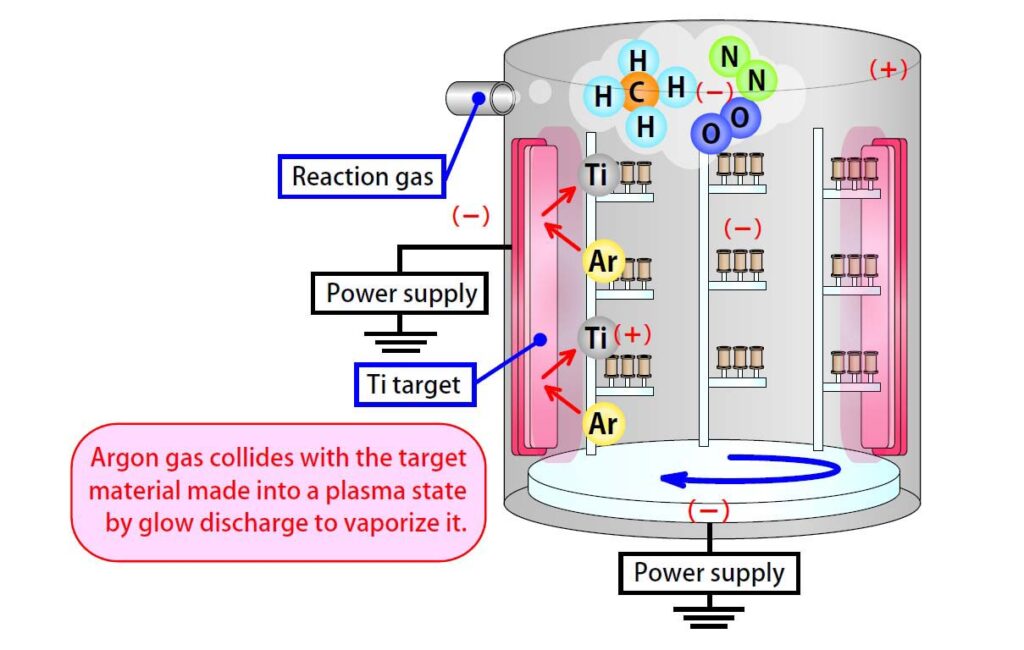

- Stable coloring on the entire surface is possible by forming a film using a workpiece mounting jig or rotating movement.

- A coating quality that is strong in wear resistance and has adhesion and conformability that does not peel off in bending tests.

- A highly corrosion-resistant film that does not discolor or corrode even in CASS tests.

- Biocompatibility is considered by using Titanium and chrome materials.

- The load temperature on the workpiece is relatively low, 160℃ to 300°C for the gas reaction film.

- We are good at appearance quality control, which is important for design products.

Processed product performance

Coloring processing for products that require wear resistance and hardness

・Fishing tackle parts (SUS)

・Building material design parts (SUS)

・Vehicle design parts (SUS)

・Watch exterior parts (SUS)

・Casing parts for digital home appliances (SUS)

・Kitchen knife, scissors (SUS)

・Screws and nuts (SUS, iron with hard Cr plating)

・Iron ball (iron with hard Cr plating)

・Golf club head (iron with hard Cr plating)

Coloring processing with biocompatible titanium film and chromium materials

Eyewear frame (titanium)

Medical equipment (titanium, SUS)

Necklace, ring (titanium, SUS)

Metal texture on plastic (metallization)

Eyewear frame (PPSU)

Shaft pipe (CFRP)

Metal plating processing as a conductive/electromagnetic wave shield on hard-to-plate materials

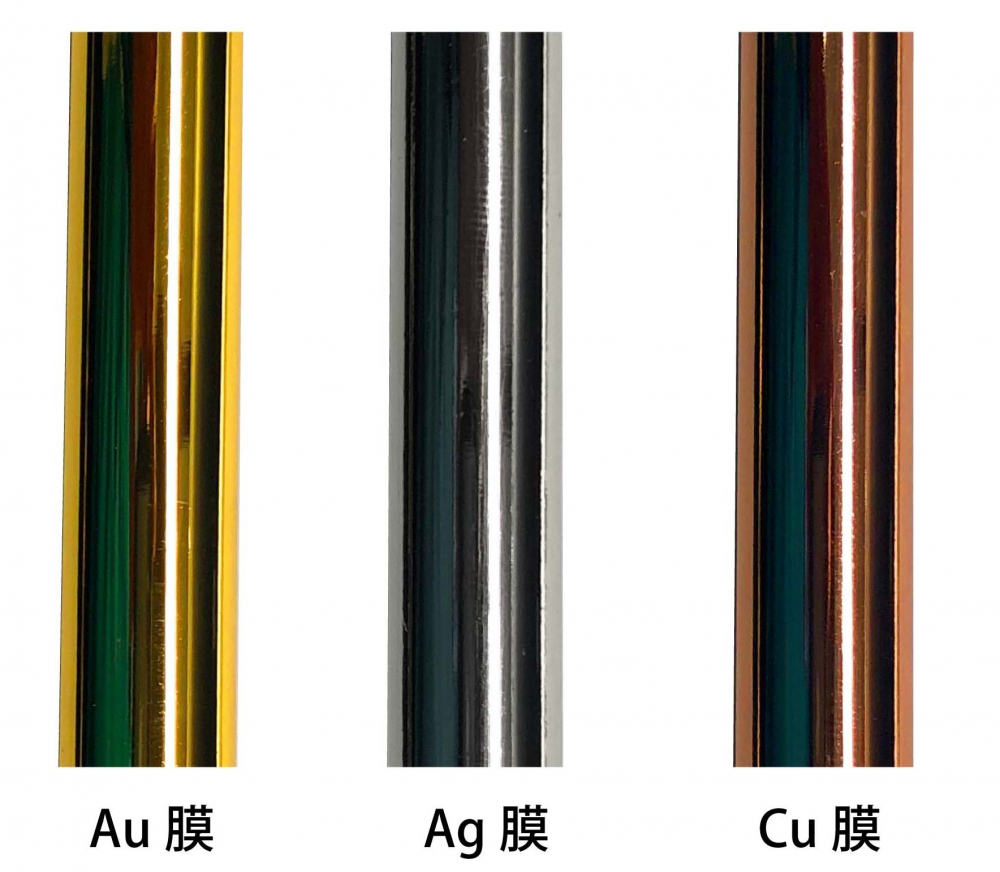

Metal films such as gold, silver, copper, and brass are sputtered to rotate and revolve the workpiece, and the entire surface is processed under a heat load of 100°C or less.

(Various plastics, coatings, glass, ceramics, FRP, chemical fibers, etc.)

*We cannot perform electromagnetic shielding effect confirmation tests such as EMC tests.

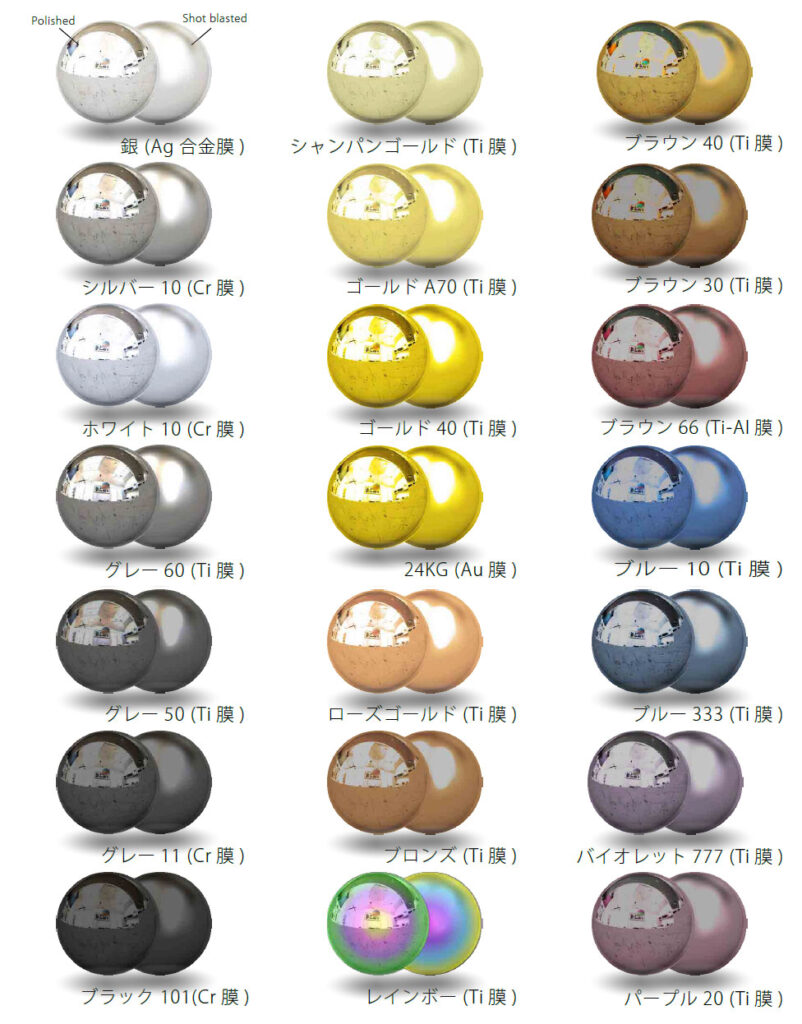

Color image of ion plating (PVD)

※ Please note that it may look different from the image monitor and the actual color.

Correspondence work size, specifications

Quality of each ion plating membrane

| IP specification name |

White 10 |

Gray 11 | Champagne Gold | Brown 40 | Black 101 | |

| Vapor deposited metal | Cr | Cr | Ti | Ti | Ti | |

| Hardness | Weght:10mN | 400~500 | 600~700 | 300~400 | 500~600 | 500~700 |

| Adhesion | Bending test Φ18mm 90° | PASS | PASS | PASS | PASS | PASS |

| Ultrasonic vibration test | PASS | PASS | PASS | PASS | PASS | |

| Impact resistance | DuPont impact test Bell 500g 500mm falling (JIS-K5600-3) |

PASS | PASS | PASS | PASS | PASS |

| Corrosion resistance | CASS test 48 hour (JIS H8502) |

PASS | PASS | PASS | PASS | PASS |

| Salt spray test 48 hour (JIS H8502) |

PASS | PASS | PASS | PASS | PASS | |

| Heat-resistant | 200℃x30 minutes | PASS | PASS | PASS | PASS | PASS |

Inquiries about ion plating

<Surface Treatment Division>

Tel : +81-778-51-5000 → 13

Fax : +81-778-51-9024