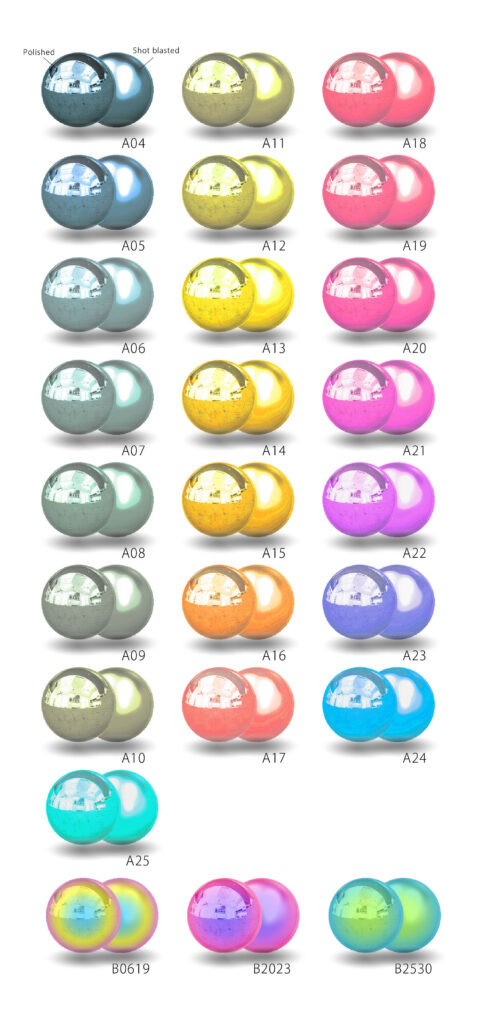

Anodizing coloring for titanium material

By oxidizing the titanium material by anodic electrolysis in the electrolytic bath, it is possible to develop color with the light interference film.

Color image of anodized coloring

*Please note that the colors may look different from the actual colors when viewed on an image monitor or printed on a printer.

Hairline and Blasting

We perform blasting and hairline processing using various media on the substrate surface for design purposes.

*Some materials and shapes cannot be processed, so please contact us.

Laser marking

Before and after coloring with each surface treatment, logos, patterns, numbering, etc. are processed with laser beams.

Processing range: about Φ110mm

Printing

- Silk screen printing

Print area: about 250x180mm - pad printing

Print area: about 50x50mm

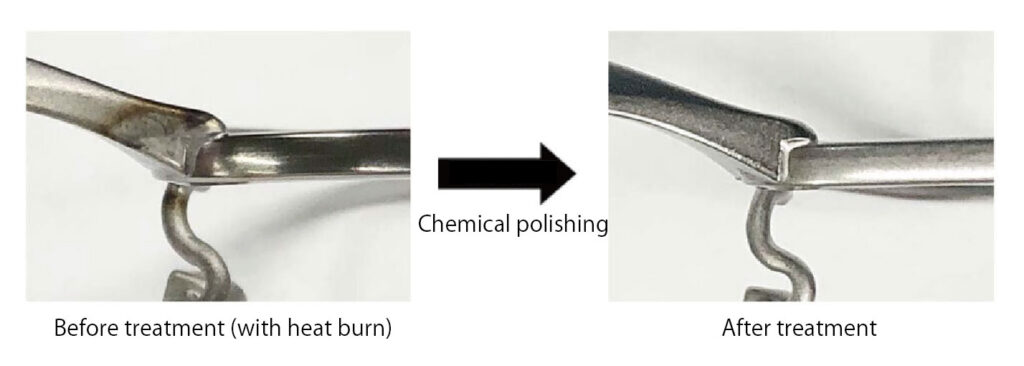

Chemical polishing for titanium material

Remove discoloration and hardened surface conditions due to welding and molding of titanium materials with a strong acid remover. By performing this process, it becomes easier to achieve a glossy finish by mirror polishing.

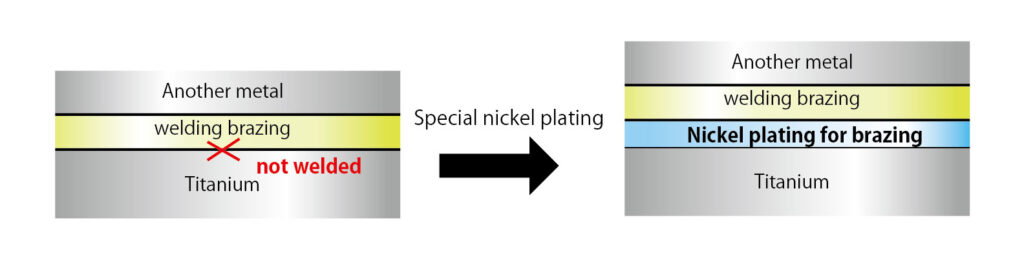

Plating for brazing

In order to join titanium (Ti) and super-elastic alloy (Ni-Ti alloy) with silver brazing, the brazing material comes to adhere closely by applying a special nickel plating process.

Inquiries about the above surface treatment

<Surface Treatment Division>

Tel : +81‐778-51-5000 → 13

Fax : +81‐778-51-9024