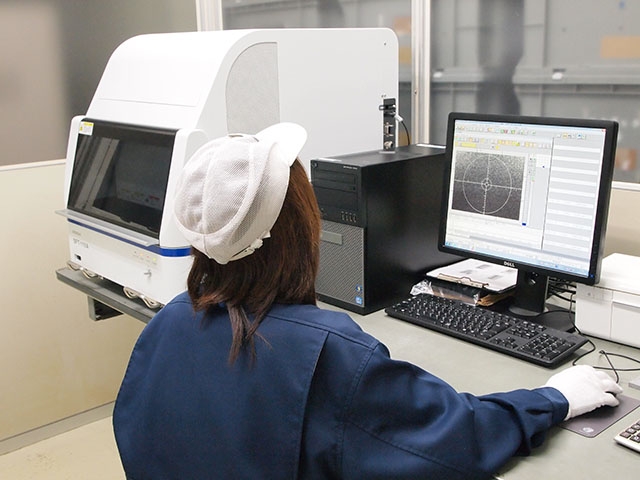

Inspection analysis system

Products that have undergone surface treatment are visually inspected and weighed one by one. After confirming that there are no scratches, stains, or unevenness, the product is delivered. In addition to manual inspection, we also measure film thickness and surface roughness to provide only good products. We have been particular about the appearance precisely because we have been performing surface treatments related to the decoration of eyeglasses for many years. At present, we also receive requests for surface treatment that takes functionality into consideration, so we have a lineup of analysis and evaluation equipment that analyzes each function such as corrosion resistance, slidability, weather resistance, and wear resistance.

Thorough production control

The history of each process is recorded in a dedicated database, and traceability operations such as overall decision making of product shipment, product quality monitoring, response to market complaints, and creation of quality assurance documents are performed. It is visualized so that members can check it on a weekly/monthly basis, and it is used to improve the site. In addition, the flow from order receipt to delivery is also managed by the production control system.

Quality Assurance System

We have acquired ISO 9001 and 14001, and manage quality and environmental management systems.