What is electrodeposition coating?

Features

Electrodeposition coating is a coating method that forms a coating film by passing electricity between the product and electrodes in the electrodeposition paint. Depending on whether the object to be coated is an anode or a cathode, it is divided into anionic electrodeposition coating and cationic electrodeposition coating. The film thickness is easy to control, and a uniform coating film can be formed even on products with complex shapes. In addition, since it is a water-based paint, the amount of organic solvent used is small, and it is effective in reducing VOCs (Volatile Organic Compounds).

Traits and Achievements

Characteristics of electrodeposition coating

・Thickness of coating and uniformity of film thickness

・Corrosion protection

・Electrical insulation

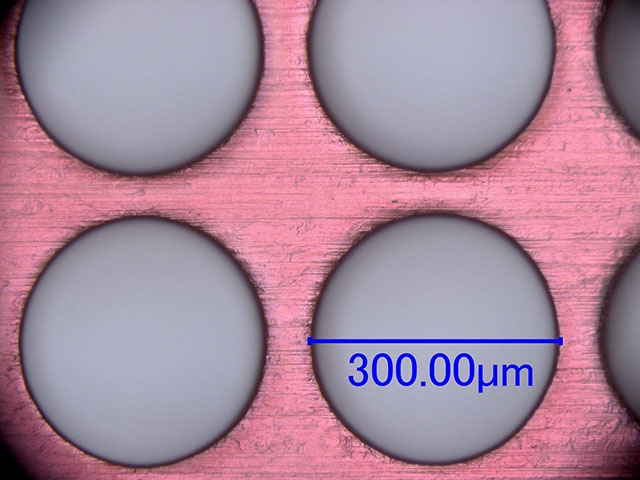

Transparent coloring

・Eyewearr frame (Ti, Ni-Ti alloy, Ni-Cu alloy)

・Household appliances housing (SUS, aluminum)

・Fishing Tackle (SUS)

・Indoor interior parts (SUS, brass)

Color image of electrodeposition coating

※ Please note that it may look different from the image monitor and the actual color.

Comparison table with various coatings (compared to our company)

|

Characteristic |

Electrodeposition coating | Electrostatic coating | Spray painting | Powder coating |

|---|---|---|---|---|

| Environmental safety | ◎ | × | × | △ |

| Coatability for complex shapes | ◎ | △ | × | △ |

| Coating thickness on edge | ○ | × | × | △ |

| Uniform coating performance | ◎ | ○ | ○ | × |

| Smoothness | ◎ | ○ | ○ | △ |

| Total caoting cost | ○ | △ | △ | △ |

Inquiries about electrodeposition coating

<Surface Treatment Division>

Tel : +81-778-51-5000 → 13

Fax : +81-778-51-9024