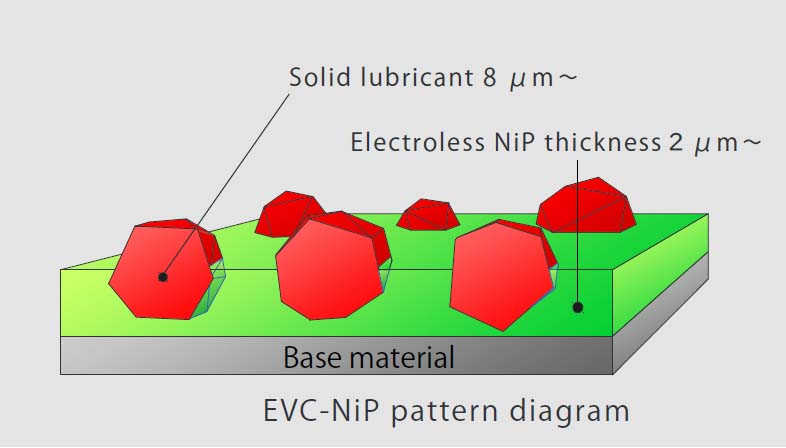

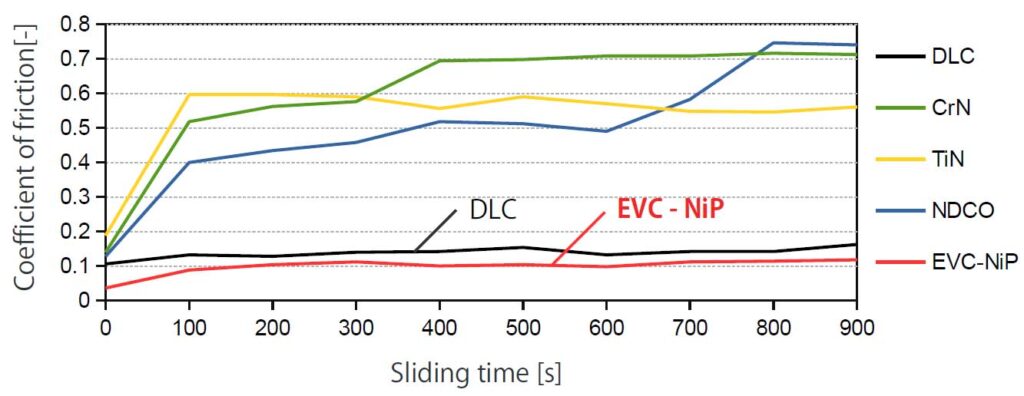

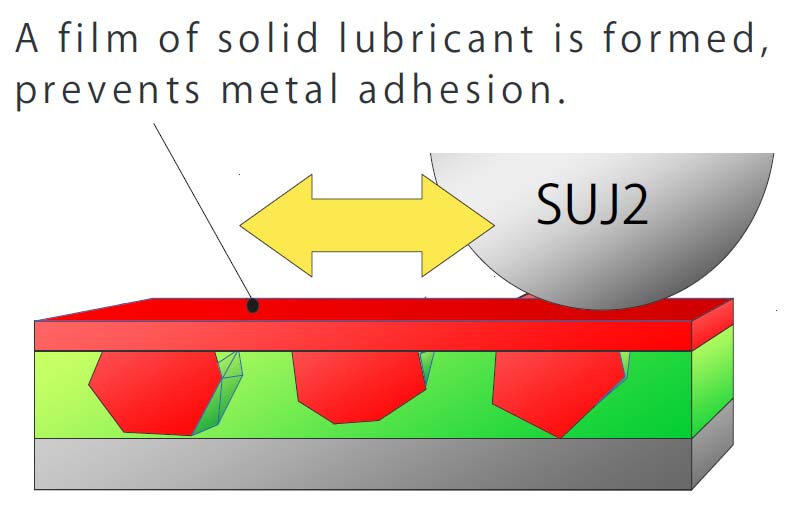

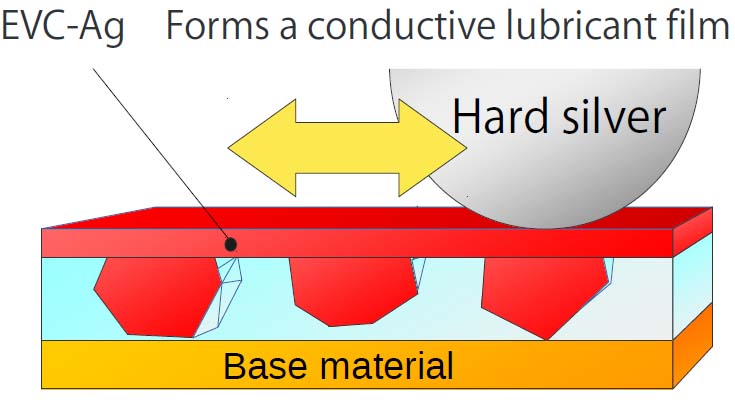

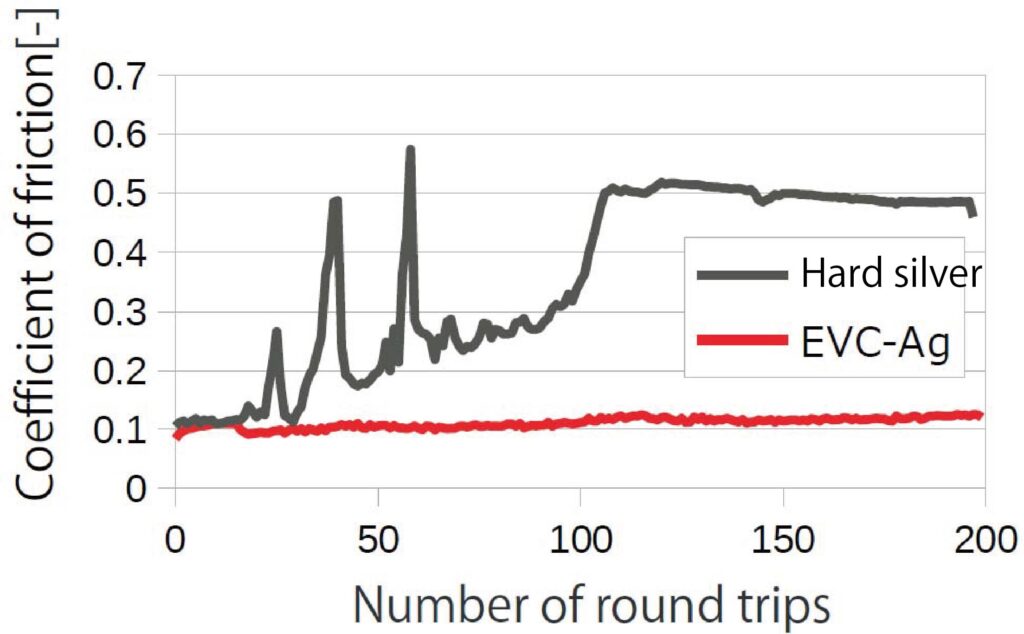

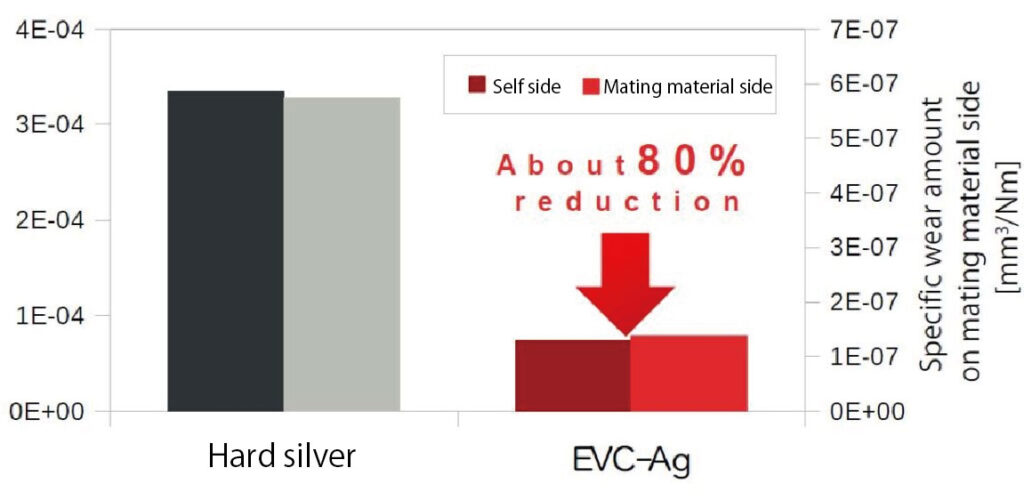

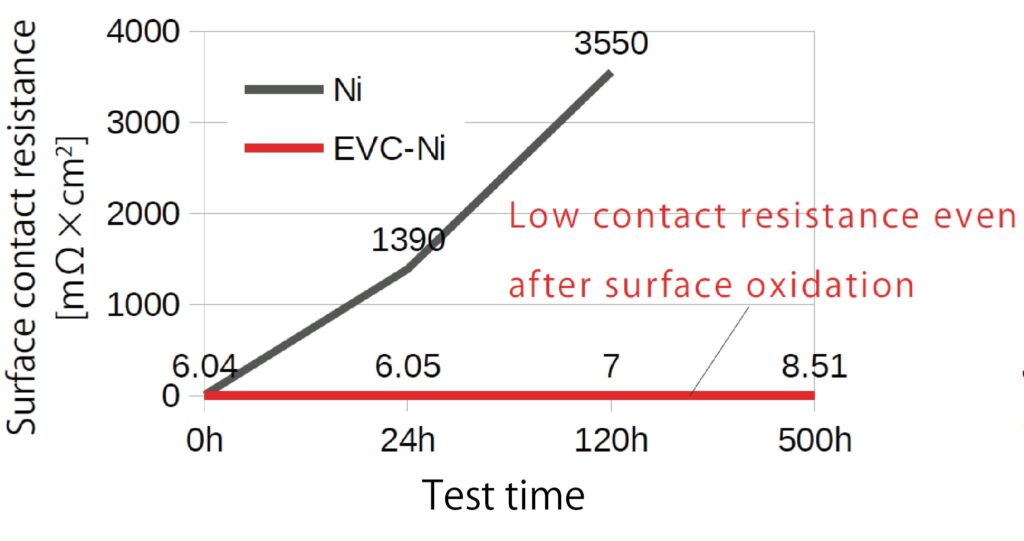

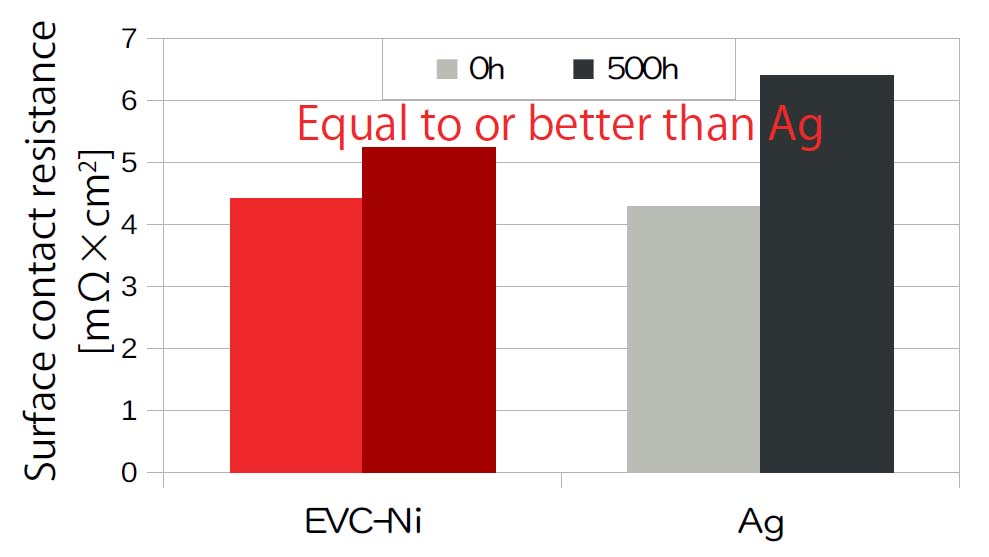

Evolved composite plating by applying NDCO dispersion technology

"Nano diamond composite plating" technology with excellent sliding properties

Patent No. 5435477

Contact for "EVC"

<New Business Development Division>

Tel : +81-778-51-5000 → 9 → Extension number 317

Fax : +81-778-51-4710

Person in charge : Mr. Osada

E-meil : Takuya_Hisaka@eyetec.co.jp